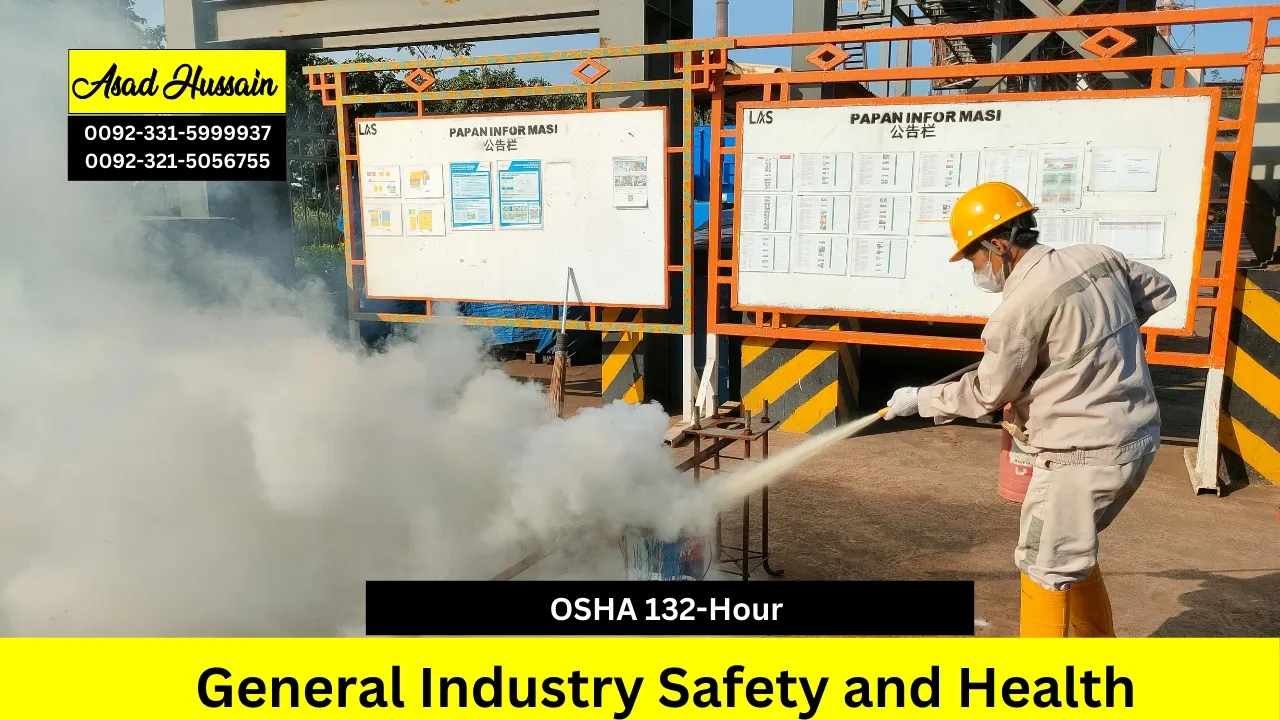

Comprehensive OSHA 132-Hour General Industry Safety and Health Diploma

The OSHA 132-Hour General Industry Safety and Health course is a comprehensive professional training programme designed to develop advanced knowledge and practical competence in workplace safety management across general industry sectors. This course focuses on strengthening understanding of occupational safety principles, hazard control measures, and regulatory compliance aligned with industry best practices. Participants gain in-depth insight into identifying workplace risks, implementing preventive strategies, and promoting safe working environments. The programme is structured to support professionals who aim to enhance safety performance, reduce incidents, and contribute effectively to organizational safety objectives.

This course places strong emphasis on real-world application of safety concepts, combining theoretical understanding with practical workplace relevance. Learners explore key areas such as hazard identification, risk assessment, emergency preparedness, ergonomics, equipment safety, and incident investigation. The curriculum supports professional development by building leadership capability, communication skills, and confidence in managing safety responsibilities. While the programme is not Ofqual regulated, it aligns with internationally recognized safety practices and supports progression toward professional certifications and diplomas in occupational safety and health disciplines.

The OSHA 132-Hour General Industry Safety and Health course is designed to empower participants with the skills needed to influence safety culture and operational excellence. Through structured learning, participants develop the ability to design safety programs, conduct inspections, and ensure compliance with safety standards across diverse industrial environments. This training supports career advancement by strengthening professional credibility and preparing learners to meet industry expectations in safety leadership, compliance management, and workplace risk control.

Program Highlights

Study Units

- Introduction to OSHA and General Industry Safety

- Walking and Working Surfaces

- Electrical Safety Standards

- Hazard Communication

- Personal Protective Equipment (PPE)

- Fire Safety and Prevention

- Machine Guarding and Lockout/Tagout

- Ergonomics

- Hazardous Materials and Waste Management

- Industrial Hygiene and Occupational Health

- Confined Spaces

- Emergency Response and Preparedness

- Accident Investigation and Recordkeeping

- Health and Safety Management Systems

- Safety and Health Training Techniques

- Special Topics and Emerging Issues

The OSHA 132-Hour General Industry Safety and Health course is designed for individuals who aim to build strong knowledge and practical skills in occupational safety and health within general industry environments. To support effective learning and successful course completion, the following entry requirements apply.

- Age Requirements: Applicants should be at least 18 years of age at the time of enrolment, demonstrating the maturity and responsibility required to understand workplace safety obligations and compliance responsibilities.

- Educational Background: A basic secondary school education or equivalent is recommended. Candidates with relevant diplomas or certificates such as occupational health and safety awards, industrial safety certificates, workplace safety diplomas, technical or vocational qualifications, engineering-related certificates, fire and safety training, or environmental health certificates will have an added advantage.

- Language Proficiency: Learners should possess basic to intermediate proficiency in the English language to comfortably understand course materials, participate in discussions, and complete written and practical assessment tasks effectively.

- Work Experience: Previous experience in general industry, manufacturing, construction, maintenance, supervision, quality control, or safety-related roles is beneficial, as it helps learners relate theoretical concepts to real workplace scenarios.

These entry requirements are intended to ensure participants are well prepared to benefit from the OSHA 132-Hour General Industry Safety and Health course and to apply the acquired knowledge confidently in improving workplace safety, compliance, and operational performance.

Learning Outcomes

The OSHA 132-Hour General Industry Safety and Health course is an advanced training program designed to provide participants with in-depth knowledge, practical skills, and compliance expertise essential for managing safety and health across diverse industrial environments. This comprehensive program equips learners with the ability to identify hazards, apply OSHA standards, implement effective safety controls, and lead workplace safety initiatives with confidence. Through structured study units, learners gain the tools necessary to strengthen compliance, reduce risks, and promote a culture of safety excellence within their organizations.

Introduction to OSHA and General Industry Safety

- Understand the mission and role of OSHA in regulating workplace safety and health

- Identify OSHA standards and regulations applicable across general industry sectors

- Explain the rights and responsibilities of employers and employees under OSHA guidelines

Walking and Working Surfaces

- Identify and assess hazards associated with walking and working surfaces in industrial environments

- Implement preventive measures to minimize slips, trips, and falls

- Conduct workplace inspections to ensure compliance with safety standards

Electrical Safety Standards

- Recognize electrical hazards and apply electrical safety requirements

- Implement safe practices for working with electricity and electrical equipment

- Conduct audits and inspections to mitigate risks and maintain compliance

Hazard Communication

- Interpret hazard communication requirements and workplace applications

- Develop and implement hazard communication programs with labeling and Safety Data Sheets

- Train employees in safe chemical handling and communication protocols

Personal Protective Equipment (PPE)

- Assess workplace hazards and determine appropriate PPE requirements

- Ensure correct use, maintenance, and storage of PPE

- Train employees on proper PPE practices to reduce exposure to risks

Fire Safety and Prevention

- Develop and enforce fire prevention and emergency response procedures

- Conduct fire risk assessments and drills to prepare employees effectively

- Ensure workplace compliance with fire safety regulations

Machine Guarding and Lockout/Tagout

- Identify hazardous machine operations and apply guarding techniques

- Develop and implement lockout/tagout procedures to control hazardous energy

- Train employees on safe machine operation and energy control practices

Ergonomics

- Identify ergonomic risks and apply ergonomic design principles

- Implement solutions to reduce musculoskeletal disorders and injuries

- Conduct ergonomic assessments to improve comfort and productivity

Hazardous Materials and Waste Management

- Identify hazardous materials and evaluate associated workplace risks

- Apply safe handling, storage, and disposal methods

- Ensure compliance with hazardous materials and waste management requirements

Industrial Hygiene and Occupational Health

- Conduct exposure assessments for chemical, physical, and biological hazards

- Apply control measures to reduce occupational health risks

- Establish and maintain occupational health monitoring programs

Confined Spaces

- Identify confined spaces and associated hazards

- Develop and implement confined space entry procedures

- Train employees on safe entry, monitoring, and emergency rescue

Emergency Response and Preparedness

- Develop emergency response plans tailored to workplace hazards

- Conduct drills and simulations to strengthen preparedness

- Train employees to respond effectively during emergencies

Accident Investigation and Recordkeeping

- Perform thorough accident investigations to identify root causes

- Implement corrective actions to prevent recurrence

- Maintain accurate and compliant incident records

Health and Safety Management Systems

- Understand key components of safety management systems

- Design and implement systems aligned with organizational needs

- Continuously improve safety performance through audits and reviews

Safety and Health Training Techniques

- Develop and deliver effective safety training programs

- Apply adult learning principles to enhance engagement

- Evaluate training outcomes and improve program effectiveness

Special Topics and Emerging Issues

- Stay updated on evolving safety challenges and industry trends

- Address emerging risks such as workplace violence and health emergencies

- Proactively manage risks linked to new technologies and work practices

By completing the OSHA 132-Hour General Industry Safety and Health course, participants gain the expertise to manage compliance, lead effective safety programs, and protect employees across a wide range of industrial environments. This advanced training strengthens professional capability while supporting safer, more productive, and well-managed workplaces.

The OSHA 132-Hour General Industry Safety and Health course is designed for individuals who play a key role in maintaining safe workplaces, ensuring regulatory compliance, and supporting effective safety management across general industry environments.

Safety Officers and HSE Professionals

- Responsible for developing, implementing, and monitoring workplace safety systems

- Involved in hazard identification, risk assessment, and incident prevention activities

- Conduct safety inspections, audits, and compliance reporting

- Manage occupational safety policies aligned with industry standards

- Lead initiatives that strengthen workplace safety culture

Industrial Supervisors and Line Managers

- Oversee day-to-day industrial operations with a focus on safe work practices

- Enforce safety procedures and operational controls on the shop floor

- Coordinate safety briefings, training, and toolbox talks

- Respond to incidents, near misses, and emergency situations

- Support continuous improvement in departmental safety performance

Engineers and Technical Professionals

- Work in manufacturing, utilities, maintenance, or production environments

- Assess machinery, equipment, and process-related safety risks

- Support implementation of engineering controls and safety solutions

- Contribute to ergonomic improvements and system safety design

- Assist with compliance inspections and technical safety evaluations

Operations and Facility Management Personnel

- Manage facilities, infrastructure, and industrial utilities safely

- Ensure safe working conditions for employees, contractors, and visitors

- Oversee hazardous materials handling, storage, and waste management

- Maintain compliance with workplace safety requirements

- Coordinate emergency preparedness and facility safety plans

Aspiring Safety Practitioners and Career Transitioners

- Individuals aiming to enter the occupational safety and health profession

- Professionals transitioning from operational or technical roles into safety roles

- Graduates seeking practical general industry safety knowledge

- Personnel looking to enhance employability in safety-focused positions

- Individuals committed to building a strong foundation in workplace safety

Quality, Compliance, and Risk Management Professionals

- Support organizational compliance and risk control initiatives

- Conduct internal reviews, audits, and safety performance assessments

- Integrate safety practices into quality and risk management systems

- Monitor regulatory alignment and corrective actions

- Promote continuous improvement and proactive risk reduction

This course supports professionals at various stages of their careers by providing practical knowledge, compliance awareness, and leadership skills needed to improve safety performance and maintain high standards across general industry workplaces.