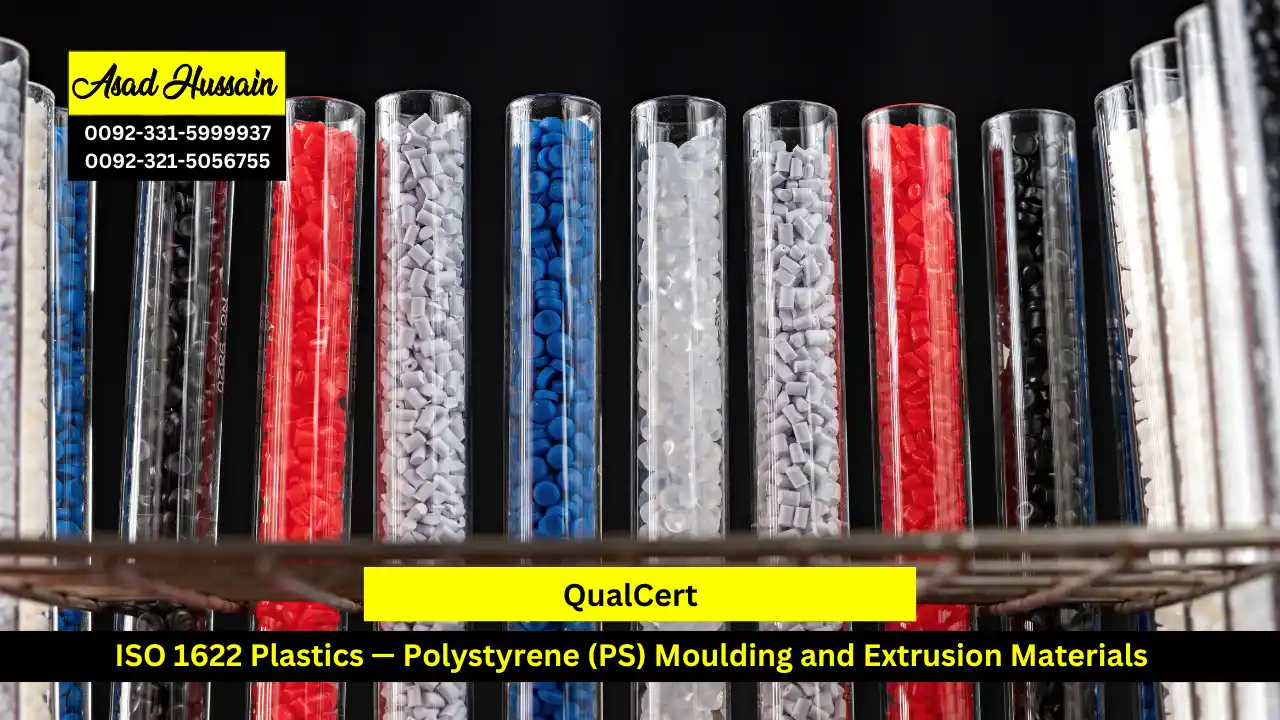

In the realm of plastics manufacturing, standards play a crucial role in ensuring quality, safety, and consistency. One such standard is ISO 1622, which specifically addresses Polystyrene (PS) moulding and extrusion materials. This international standard is vital for manufacturers, engineers, and quality assurance professionals involved in the production and use of PS materials. In this blog post, we’ll delve into the key aspects of ISO 1622, its significance, and how it impacts the industry.

ISO 1622 is an international standard developed by the International Organization for Standardization (ISO). It outlines the specifications and testing methods for polystyrene (PS) moulding and extrusion materials. The standard ensures that PS materials meet specific performance criteria, which are crucial for their intended applications in various industries, including packaging, construction, and consumer goods.

ISO 1622 emphasizes the importance of quality control throughout the manufacturing process. It provides guidelines for maintaining consistency in material properties and ensuring that the final products meet the specified standards. This includes recommendations for sampling, testing frequency, and documentation.

ISO 1622 is a critical standard for polystyrene moulding and extrusion materials, providing guidelines for material specifications, testing methods, and quality control. By adhering to this standard, manufacturers can ensure the quality, safety, and consistency of their products, facilitating international trade and enhancing consumer safety. Whether you’re a manufacturer, engineer, or quality assurance professional, understanding and applying ISO 1622 is essential for success in the plastics industry.

Program Highlights

Mandatory Units

- Introduction to Polystyrene

- Material Composition and Requirements

- Physical and Mechanical Properties

- Thermal and Dimensional Stability

- Environmental Resistance and Sustainability

- Testing Methodologies

- Applications and Case Studies

- Basic Knowledge of Plastics

- Understanding of Material Testing

- Technical Background

- Industry Experience

- Language Proficiency

Introduction to Polystyrene

- Understand the Basics: Define polystyrene and its various types (e.g., general-purpose polystyrene (GPPS) and high-impact polystyrene (HIPS)).

- Historical Context: Describe the development and evolution of polystyrene as a material.

- Key Uses: Identify common applications of polystyrene in various industries.

- Production Overview: Outline the general process of manufacturing polystyrene, including polymerization techniques.

Material Composition and Requirements

- Chemical Composition: Describe the chemical structure of polystyrene and its impact on material properties.

- Material Specifications: Explain the requirements for polystyrene materials as outlined by ISO 1622.

- Grades and Types: Differentiate between various grades of polystyrene based on their composition and intended use.

- Regulatory Standards: Identify relevant standards and regulations governing polystyrene materials.

Physical and Mechanical Properties

- Physical Properties: Discuss the key physical properties of polystyrene, including density, hardness, and clarity.

- Mechanical Properties: Analyze the mechanical properties such as tensile strength, impact resistance, and elasticity.

- Performance Metrics: Assess how these properties influence the material’s suitability for different applications.

- Testing Methods: Explain standard testing methods for evaluating physical and mechanical properties.

Thermal and Dimensional Stability

- Thermal Properties: Describe the thermal characteristics of polystyrene, including melting point, thermal conductivity, and heat deflection temperature.

- Dimensional Stability: Explain how polystyrene maintains its shape and dimensions under various conditions.

- Temperature Effects: Analyze the effects of temperature fluctuations on the material’s performance.

- Applications Impact: Discuss the implications of thermal and dimensional stability for different applications.

Environmental Resistance and Sustainability

- Environmental Resistance: Identify the factors affecting polystyrene’s resistance to environmental conditions such as moisture, UV radiation, and chemicals.

- Sustainability Considerations: Discuss the environmental impact of polystyrene production and disposal.

- Recycling and Disposal: Explore methods for recycling polystyrene and reducing its environmental footprint.

- Sustainable Alternatives: Evaluate alternative materials and technologies aimed at improving sustainability.

Testing Methodologies

- Standard Tests: Describe common testing methodologies for evaluating polystyrene properties, including tensile, impact, and flow tests.

- Test Procedures: Explain the procedures for conducting tests as specified by ISO 1622.

- Interpreting Results: Analyze and interpret test results to assess material quality and performance.

- Quality Control: Discuss the role of testing in quality control and assurance.

Applications and Case Studies

- Common Applications: Identify and describe various applications of polystyrene, such as packaging, construction, and consumer goods.

- Case Studies: Review specific case studies that illustrate the use of polystyrene in real-world scenarios.

- Performance Evaluation: Assess the performance of polystyrene in different applications based on case studies.

- Best Practices: Discuss best practices for selecting and using polystyrene in various applications.

This course is designed for professionals and students involved in the plastics industry who seek a deep understanding of polystyrene materials and their applications. It is particularly valuable for material scientists, chemical engineers, product designers, and quality assurance specialists who work with or are interested in polystyrene (PS) moulding and extrusion. Additionally, individuals in regulatory roles, sustainability officers, and those responsible for product development and testing will find this course beneficial for ensuring compliance with international standards and enhancing the performance and sustainability of their products. Whether you’re aiming to improve material quality, expand your expertise, or stay updated with industry standards, this course provides essential knowledge and practical insights for effective application and management of polystyrene materials.